Svitlana Panova has led the limited liability company A – Soft Pro under the brand “Areal” from Kramatorsk since 2014. She worked in the hotel business in Crimea before deciding to change her profession and direction of development.

“If you can organize several people and motivate them, it doesn’t matter what kind of business it is. Business processes in different industries are very similar. Therefore, it was not difficult for me to change and master a new vector of development,” says Panova, Areal co-owner and director.

From 2014 to 2022, under Panova’s leadership, the company grew in number of employees, and increased its number of clients 20 times. Networking and market promotion among businesses in Donetsk Oblast contributed to this growth.

By February this year, the company employed 26 people, most of them IT specialists. Areal is a member of the public union Eastern Ukrainian IT cluster, which was created in 2020 with the assistance of Economic Resilience Activity (ERA).

The company develops software for accountants, writes programs for enterprises in the housing and communal services sphere, and develops various applications. Clients are enterprises in the budgetary, communal, and security sectors of Donetsk, Kharkiv and Luhansk Oblasts. For example, in Kramatorsk, Areal developed a convenient single bill for residents to pay for utilities. The company also serviced all housing intercoms in eastern Ukraine, from Kharkiv to Dnipro and Poltava, and cooperated with Donetsk Oblast State Administration.

In April, due to the war the company relocated from Kramatorsk to Lviv. Not everyone agreed to move to Lviv, so the company now has a team of 12 employees. The same number of employees have left Ukraine and are now working in foreign companies. The company rented an apartment in Lviv that became an office for internally displaced people from Donetsk Oblast.

“We are interested in creating a new powerful team that will promote our products on the market. Before, clients trusted the brand; now they trust people, the team that creates a certain product, so having a good team is extremely important,” says Panova.

A new development by IT specialists from Kramatorsk is software for accounting. The software can be installed on a computer, and Areal specialists will help to transfer databases previously developed by the client, and advise the company.

“We are the only ones in Ukraine who help clients not only to install our program, but also to transfer databases of many years. Other IT companies rarely do this. We support our customers and treat their needs as our own; this is the only way to build a quality service. We offer clients to purchase this service from Areal-accounting for 1 hryvnia, so that customers can appreciate its advantages and abandon use of the widespread Russian product 1C. I have experience in accounting work and I often try the product myself to understand whether it is convenient to use,” Panova says.

Seventy percent of Areal clients have also left Donetsk Oblast and are now working in various regions of Ukraine. A third, with whom the IT specialists keep in touch, remain in dangerous areas where there is shelling and destruction every day.

The internally displaced company needs to attract new partners, which is not easy in a new business environment, but Areal actively participates in IT conferences and is getting to know local private businesses, utility companies and state organizations. Specialists are currently developing a program for military trade that will improve and facilitate communication with the customers.

Svitlana Panova, as a member of the Women in Business and Technology women’s network, also invites women entrepreneurs to cooperate.

She believes that Areal will return home because, according to her, her soul remains in Kramatorsk.

Specialists of Economic Resilience Activity (ERA) helped Perepelytsia to sell part of his finished beehives in order to have working capital for moving.

Specialists of Economic Resilience Activity (ERA) helped Perepelytsia to sell part of his finished beehives in order to have working capital for moving.

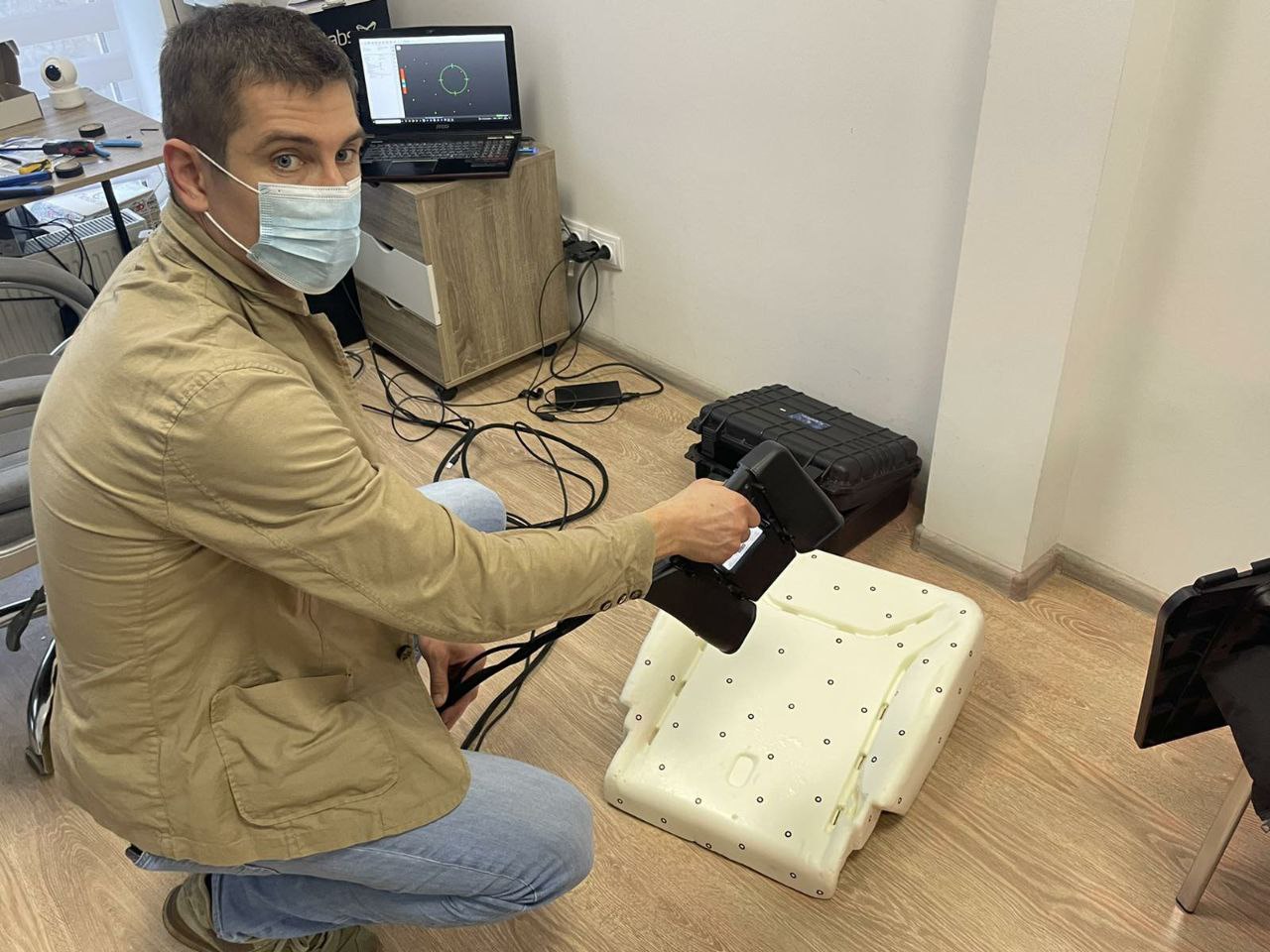

Both girls and boys come to robotics master classes supported by the Institute of Economic Research and Policy Consulting. Even during the summer, there are always children willing to participate. Information about the arrival of trainers is distributed in groups among the educational institutions of relevant towns. During three months of the Looking into the Future project, Telychko should attract 750 children from regional cities and small towns of western Ukraine.

Both girls and boys come to robotics master classes supported by the Institute of Economic Research and Policy Consulting. Even during the summer, there are always children willing to participate. Information about the arrival of trainers is distributed in groups among the educational institutions of relevant towns. During three months of the Looking into the Future project, Telychko should attract 750 children from regional cities and small towns of western Ukraine.